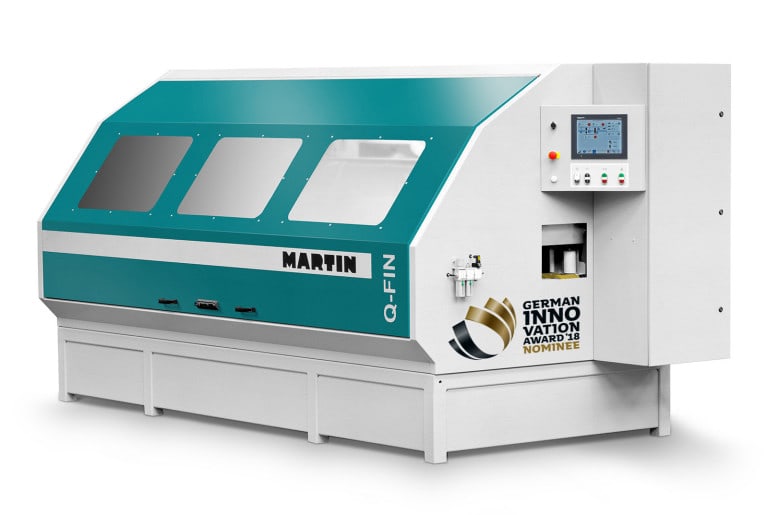

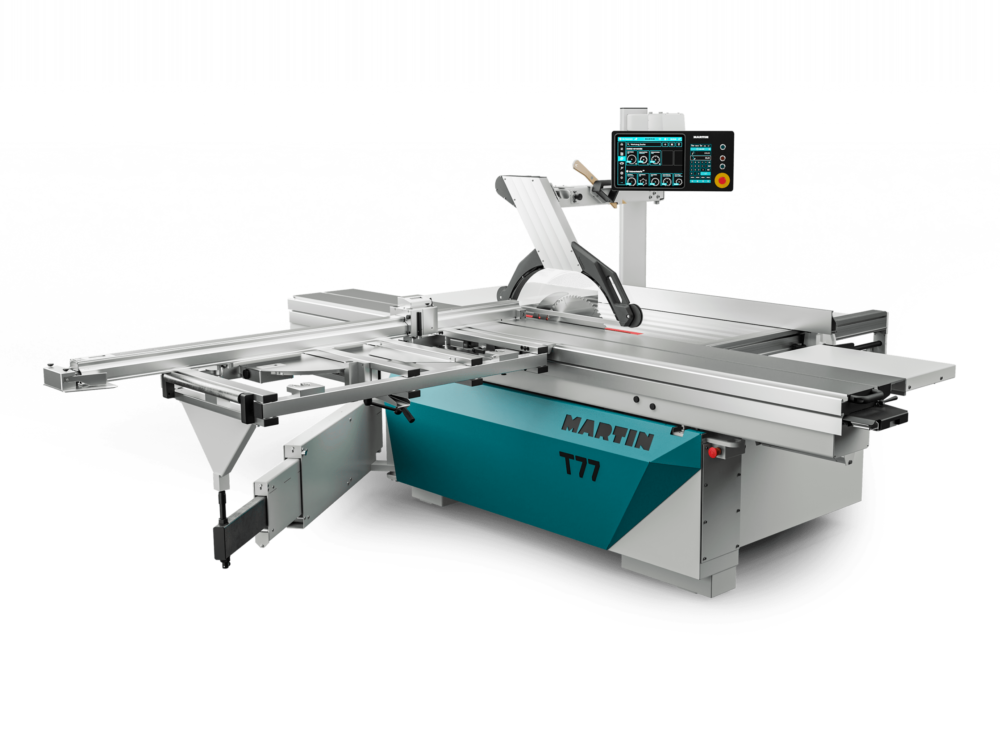

Präzision und Robustheit

Denkmalpflege auf höchstem Niveau

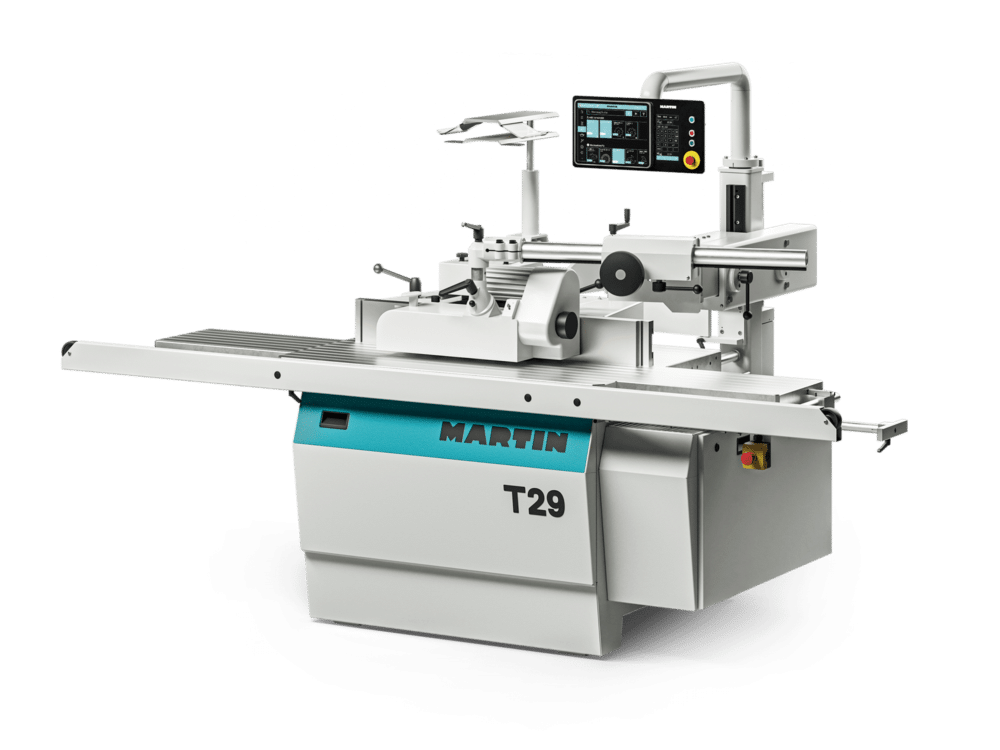

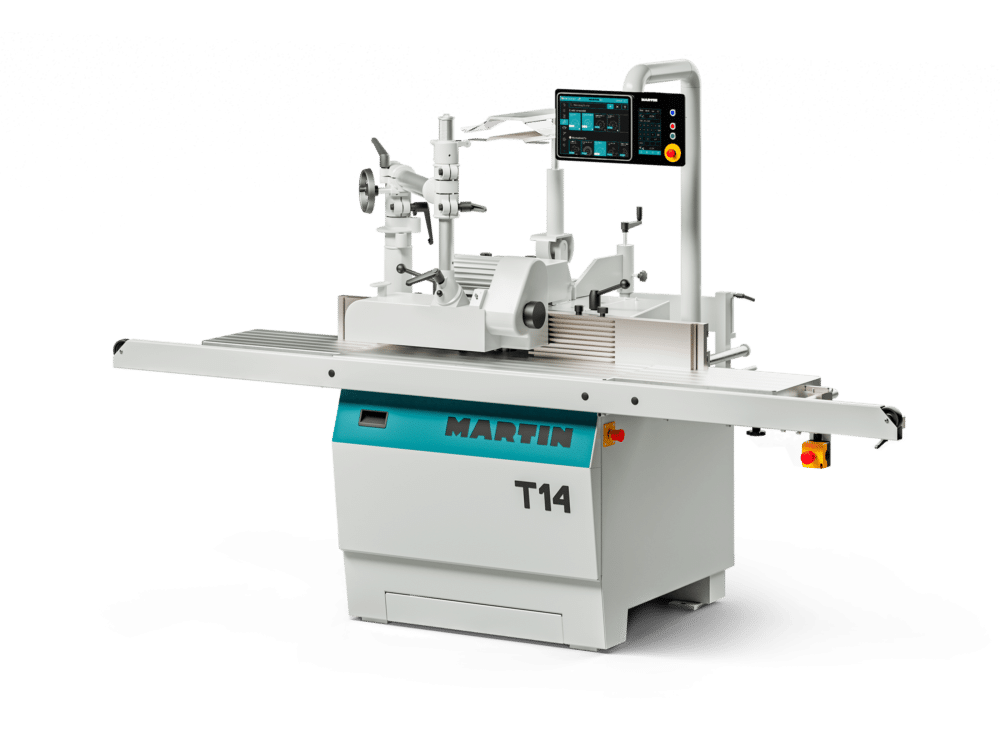

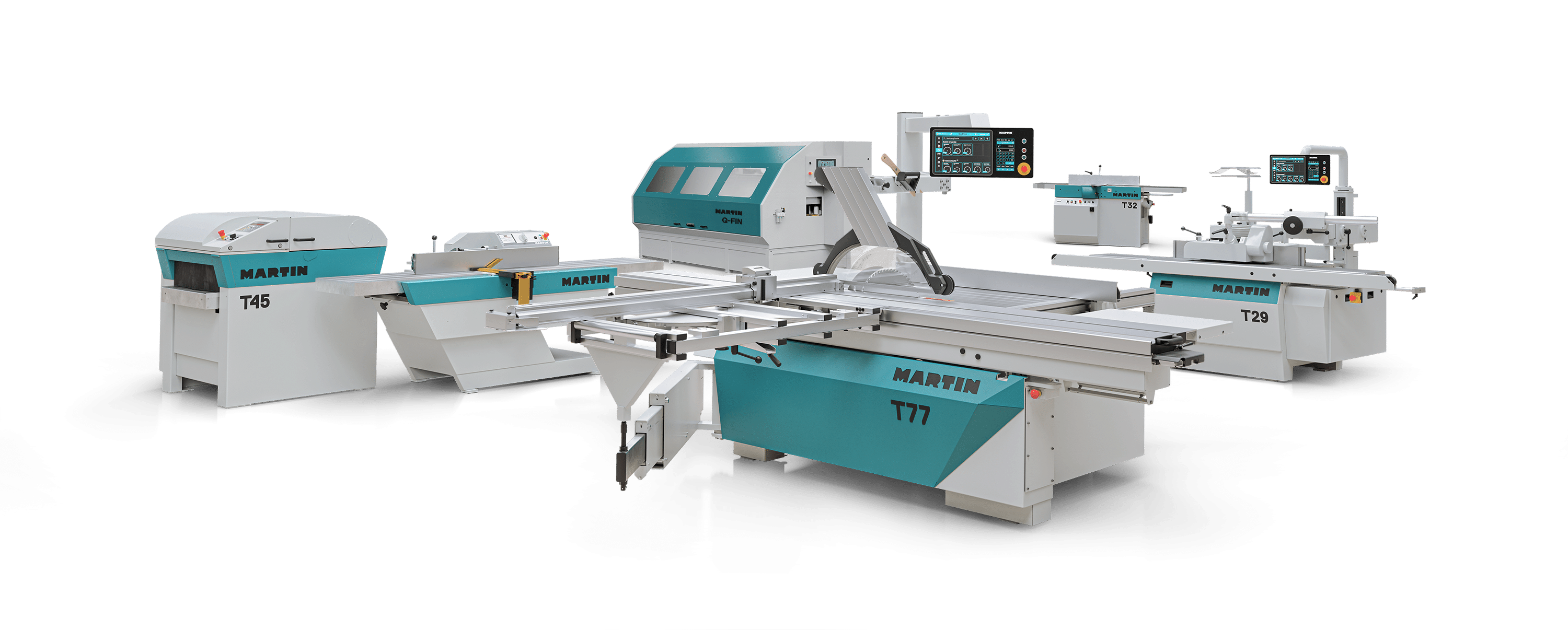

Seit der politischen Wende arbeiten wir mit Maschinen von MARTIN. Wir schätzen dabei die Präzision und gleichzeitig Robustheit der Anlagen ebenso, wie die gute Handhabbarkeit. Sie sind nicht nur gut durchdacht, sondern auch verarbeitet. Die Zuverlässigkeit der Maschinen, als auch die im Servicebereich macht das Arbeiten mit MARTIN unkompliziert und angenehm. Vielen Dank an alle Mitarbeiter!

Jörg Spatzier M.A.

Tischlerei Spatzier GmbH