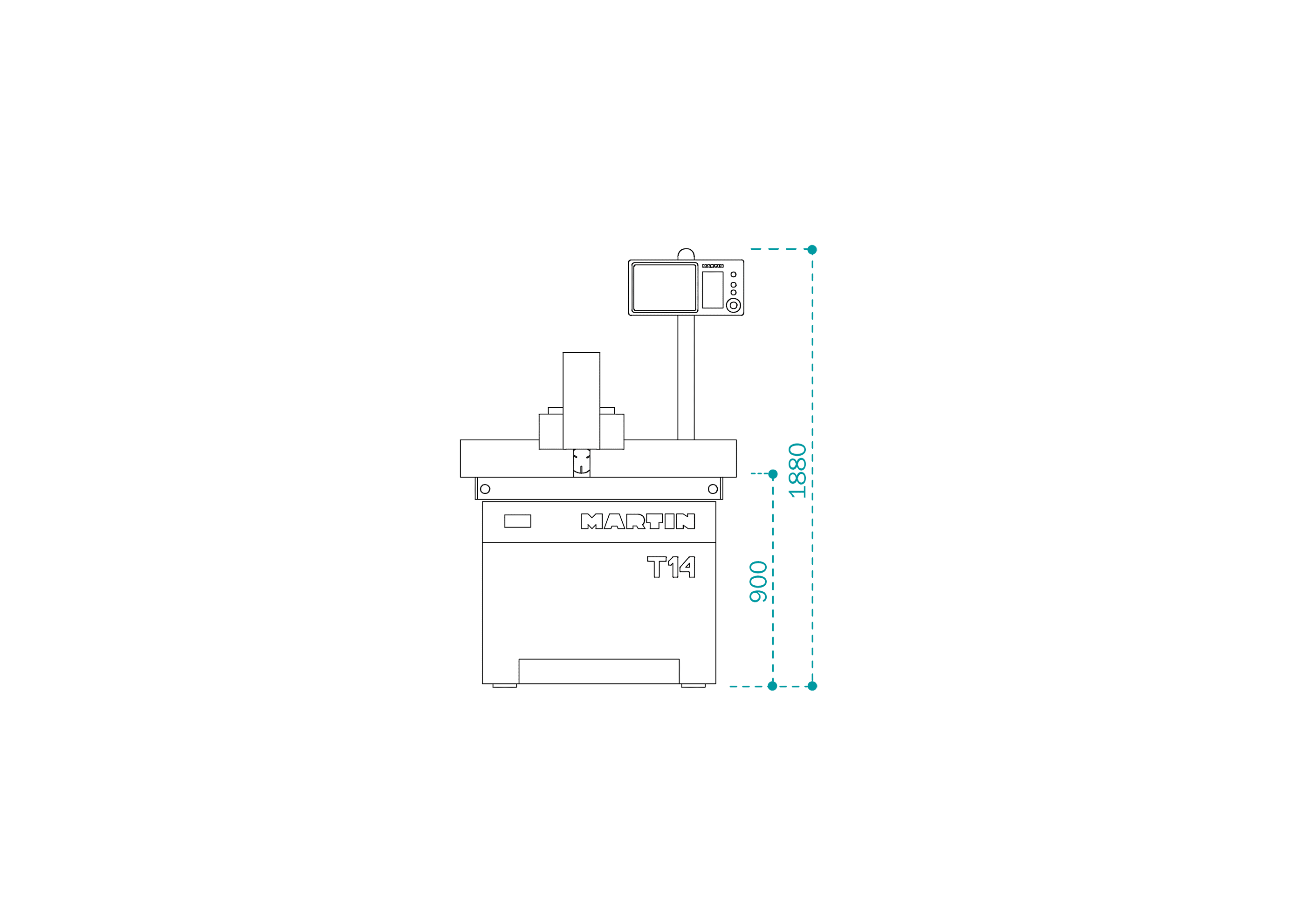

T14

Compact in class,

premium in performance.

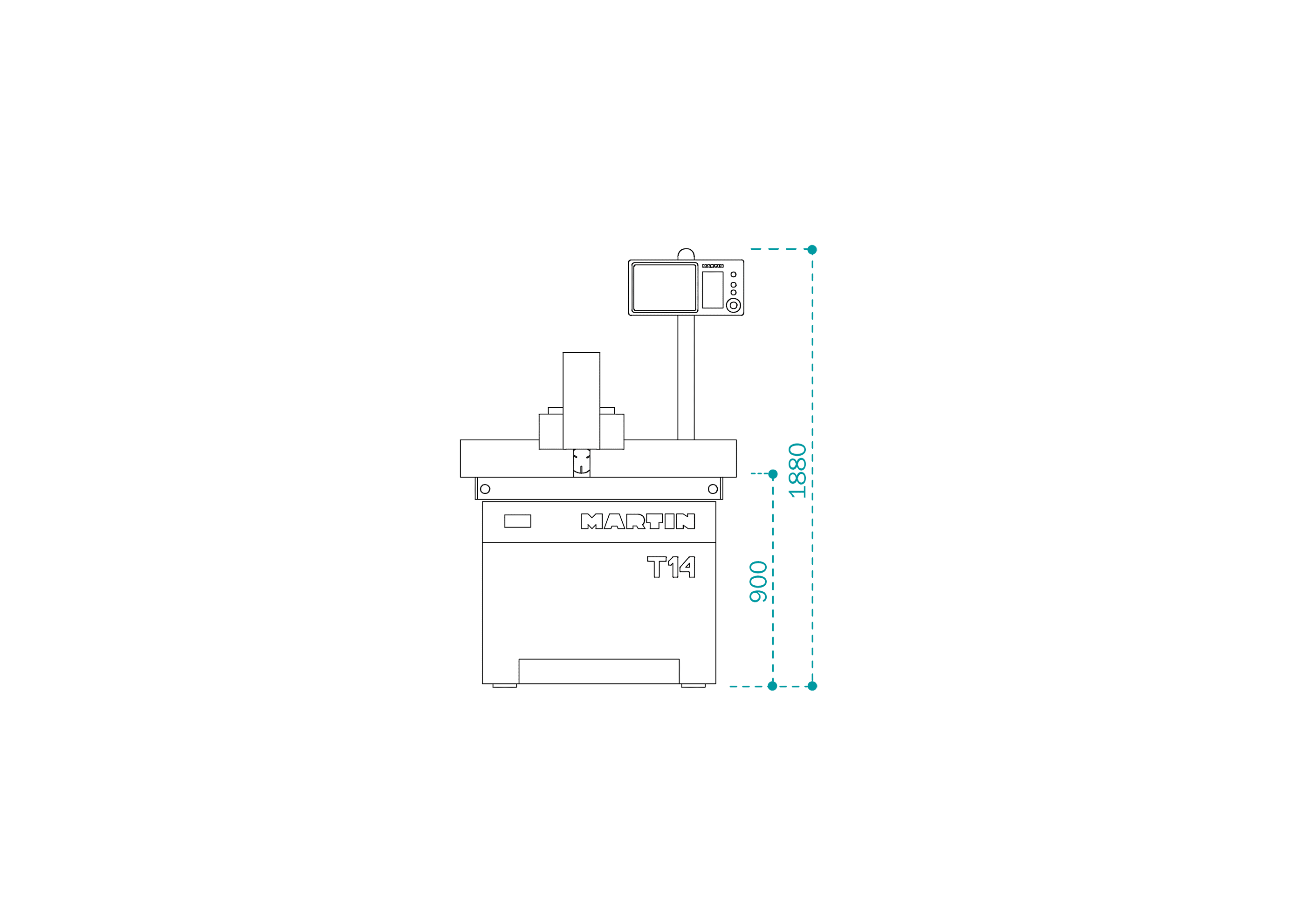

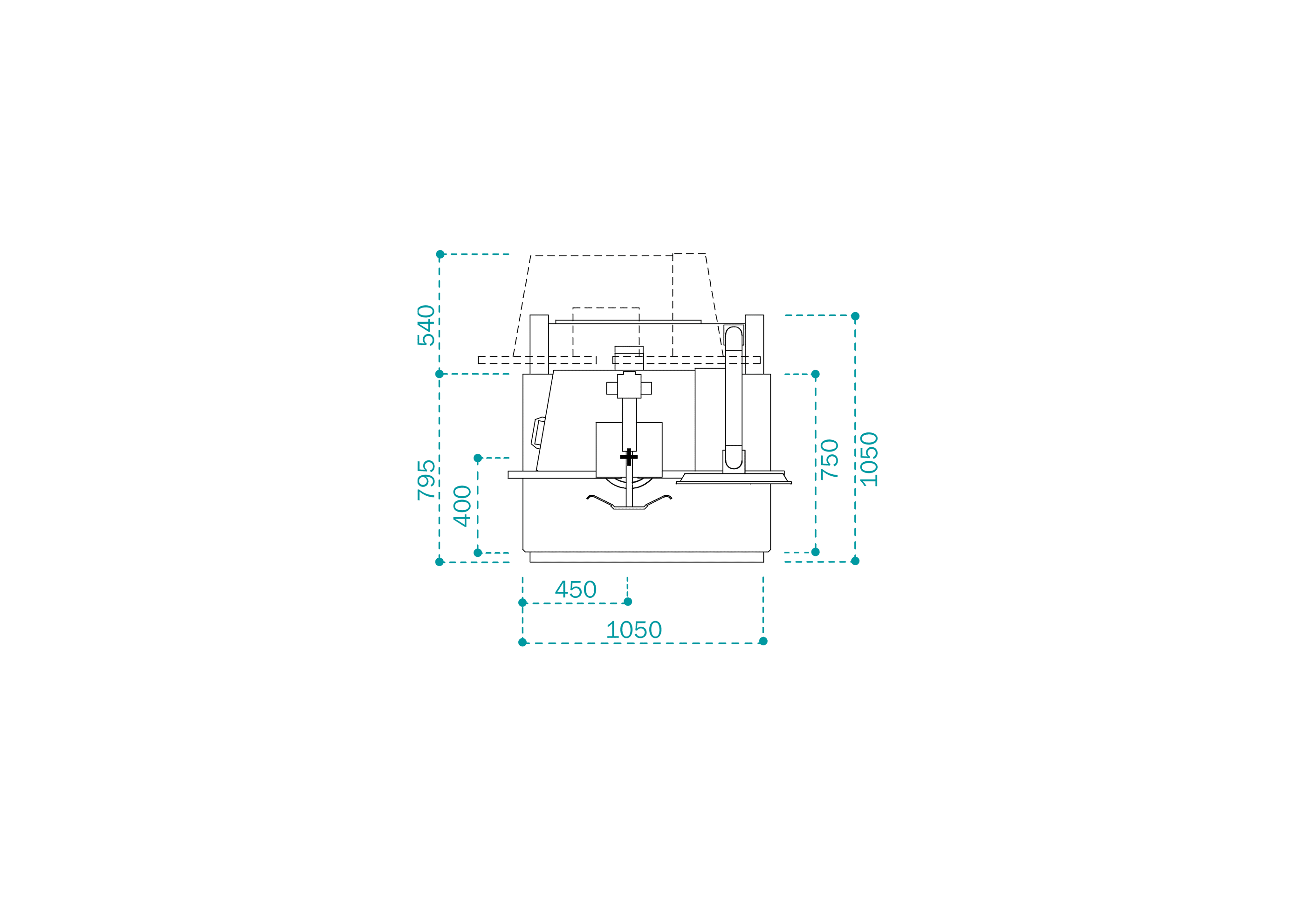

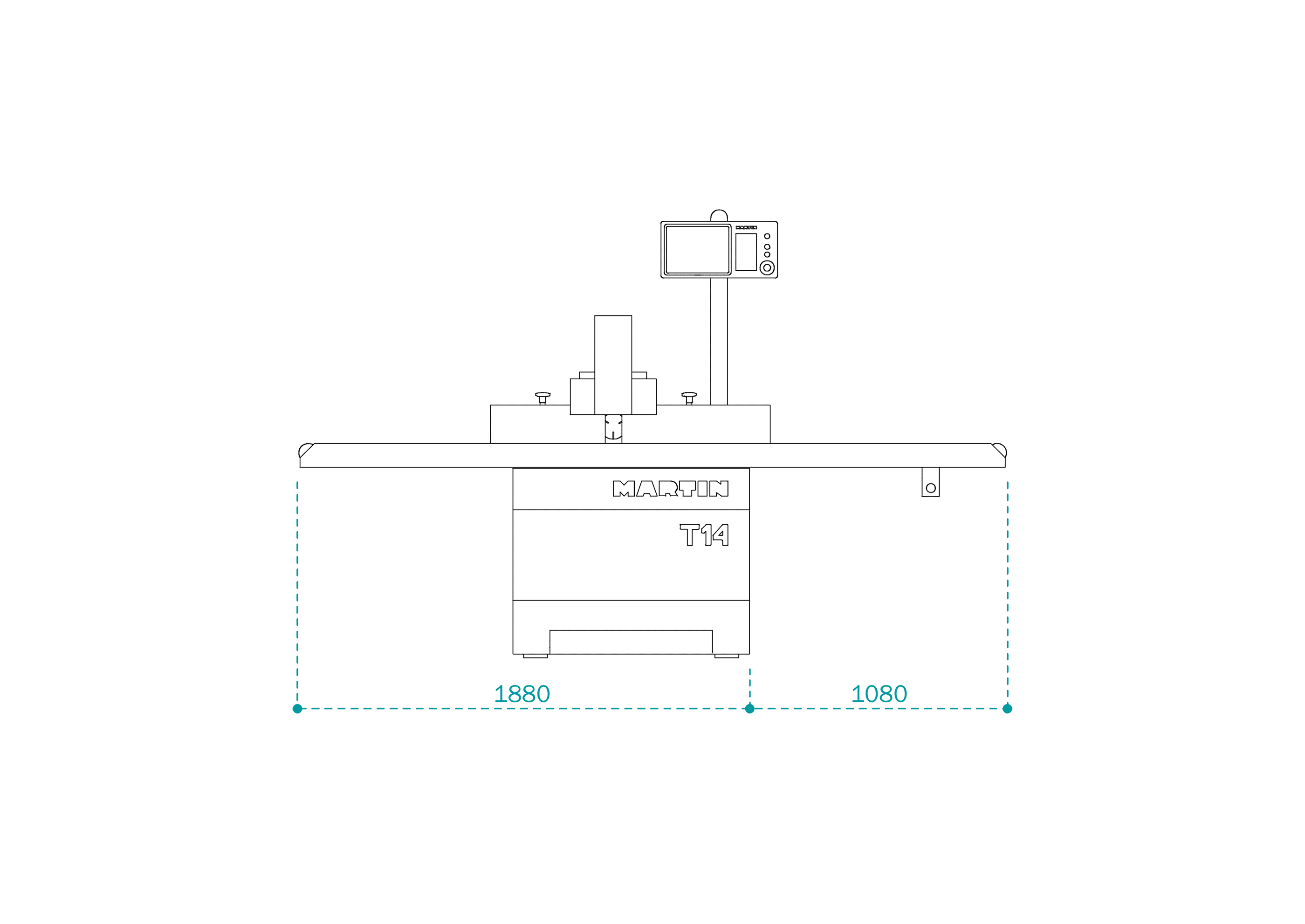

The T14 is our compact spindle moulder with all the premium features of a MARTIN machine. Take for instance, its state-of-the-art yet easy-to-use control system which opens up all networking possibilities to you. And then there is also its uniquely precise and robust machine construction. Added together, these two features will give you the best possible value for money.

The T14 is the ideal machine for any company – either as an affordable entry into the MARTIN world of moulding or as an effective way to expand your manufacturing options in trade and industry.

With its individual customisation options, this is the perfect spindle moulder for a wide variety of applications. The compact T14 spindle moulder is also worth getting excited about.

Since over 100 years

Made in Germany.

Arbor change systems

The HSK quick-change system is the number one choice for power users who often change the arbor of the complete arbor/tool units. The system works fully tool-free and is compatible with the CNC processing centres of leading manufacturers. So you can use suitable CNC machining centre tools directly on the spindle moulder without any problem, thereby relieving this expensive machine from capacity-consuming traversing moulding tasks.

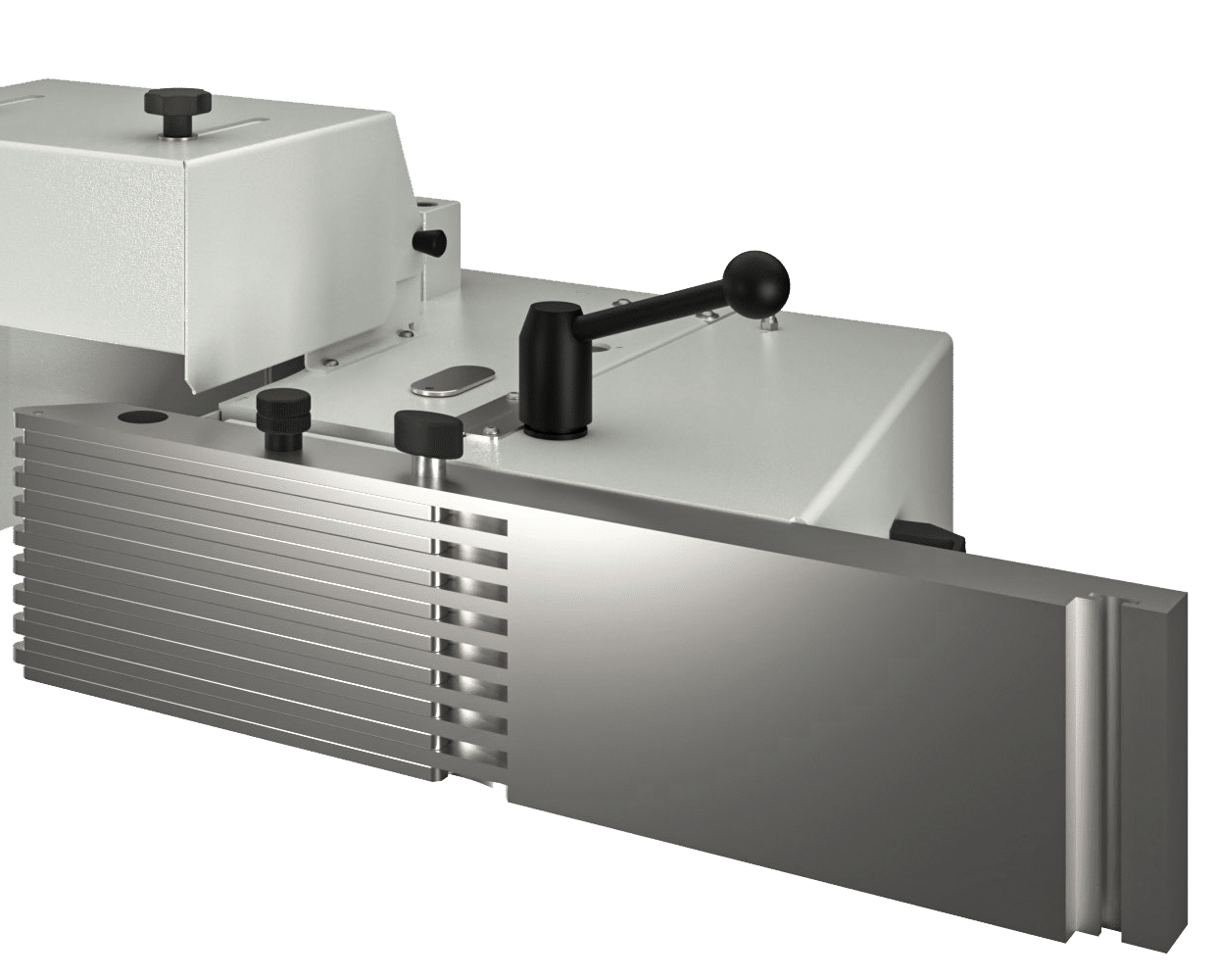

Fence jaws

The fence opening should always be closed in the firmly way so that the workpiece can be properly guided as it moves along the fence. This can be achieved with the tried and tested integral fence. The bars of the jaws, which are made of hard-coated aluminium, can be easily folded into position and released again, and the height position can also be varied. The bar cassettes can be easily removed to allow working with a pre-set board.

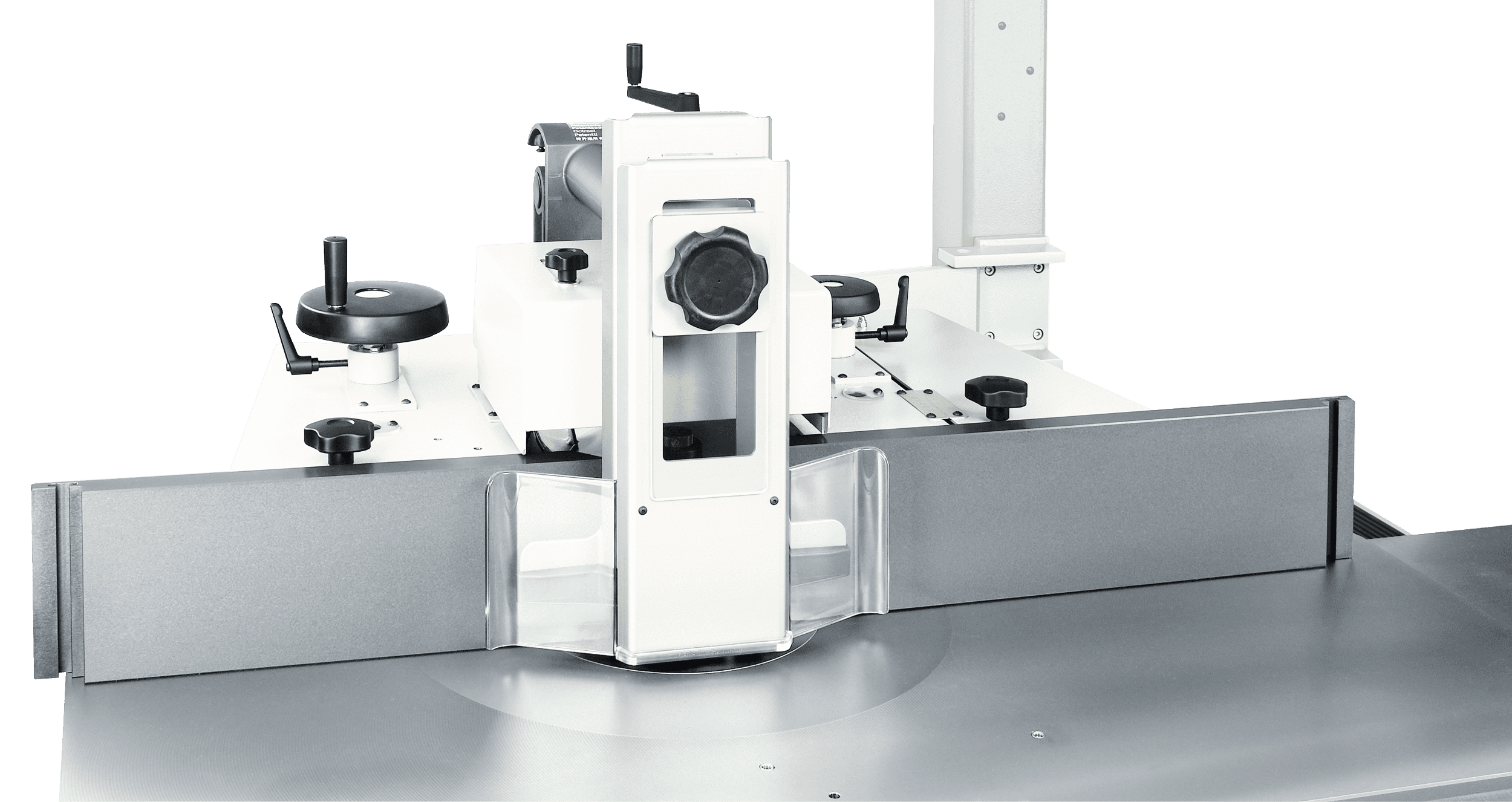

May we present:

The new digital control panel

Cloud-based data storage

Cloud-supported work provides the data base for controlling the machine and also for many advanced features – which are available anywhere and any time. For effective digital and mobile work.

Anywhere, any time

An Apple iPad with a large screen and a WLAN-controlled connection serves as an adaptive control unit. The mobile device makes it possible to control the machine from any location.

Integrated touchdisplay

The permanently integrated, touch-sensitive console serves as the operating unit and can control all the machine’s functions.

An abundance of tools

Only with the ConnectApp can the full potential of Cloud-supported work processes be realised. In addition to the machine controls, it also opens up a whole range of administrative functions and wizards to support you.

Digital

user interface

for networked

working.

Your material:

our strength.

What connects us with our customers: the passion for the precious material wood.

Anyone who works with wood must love it. The variety and the warmth it gives create enthusiasm for the most pristine of all materials. The wide range of possible applications offers room for creativity to unfold. Our machines are built for these passionate thinking and working people.

When plastic is your business!

The almost unlimited technical properties make plastics a fascinating material for a wide range of applications in trade and industry. MARTIN planers are the tools of choice when it comes to manufacturing these products. With our decades of experience in the machining of plastics, we always offer the perfect solution, even for very special machining operations.

Accurate results even with light metals.

Planing light metals and alloys with a weight content of less than 80 % magnesium is a demanding task for any sliding table saw. It is no coincidence that well-known aluminium processors rely on MARTIN. The robust construction, the powerful motors and the extensive accessories make the MARTIN planers the ideal tool for all those who value precise cutting.

More Highlights

Fence jaw clamping system AutoLock

Fence jaws need to be moved on a regular basis in order to optimise the fence opening to suit the tool. But all too often, clamping is forgotten about afterwards and the jaws are damaged. The optional AutoLock fence jaw clamping system ensures secure clamping of standard and integral fence jaws in a simple and safe manner. The jaws are always clamped securely by spring force and the clamping is only released for setting with the easily accessible levers. Completely without any electrics or pneumatics.

Fence plates

The fence opening should always be closed in the firmly way so that the workpiece can be properly guided as it moves along the fence. This can be achieved with the tried and tested integral fence. The bars of the jaws, which are made of hard-coated aluminium, can be easily folded into position and released again, and the height position can also be varied. The bar cassettes can be easily removed to allow working with a pre-set board. If you opt for the standard jaws, the optional guide rails will help you to close the opening of this fence in the best possible way.

SK40 cutter arbor clamping system

The DornFix standard quick-change system is the perfect solution for everyone wishing to adjust the arbor diameter time and again.

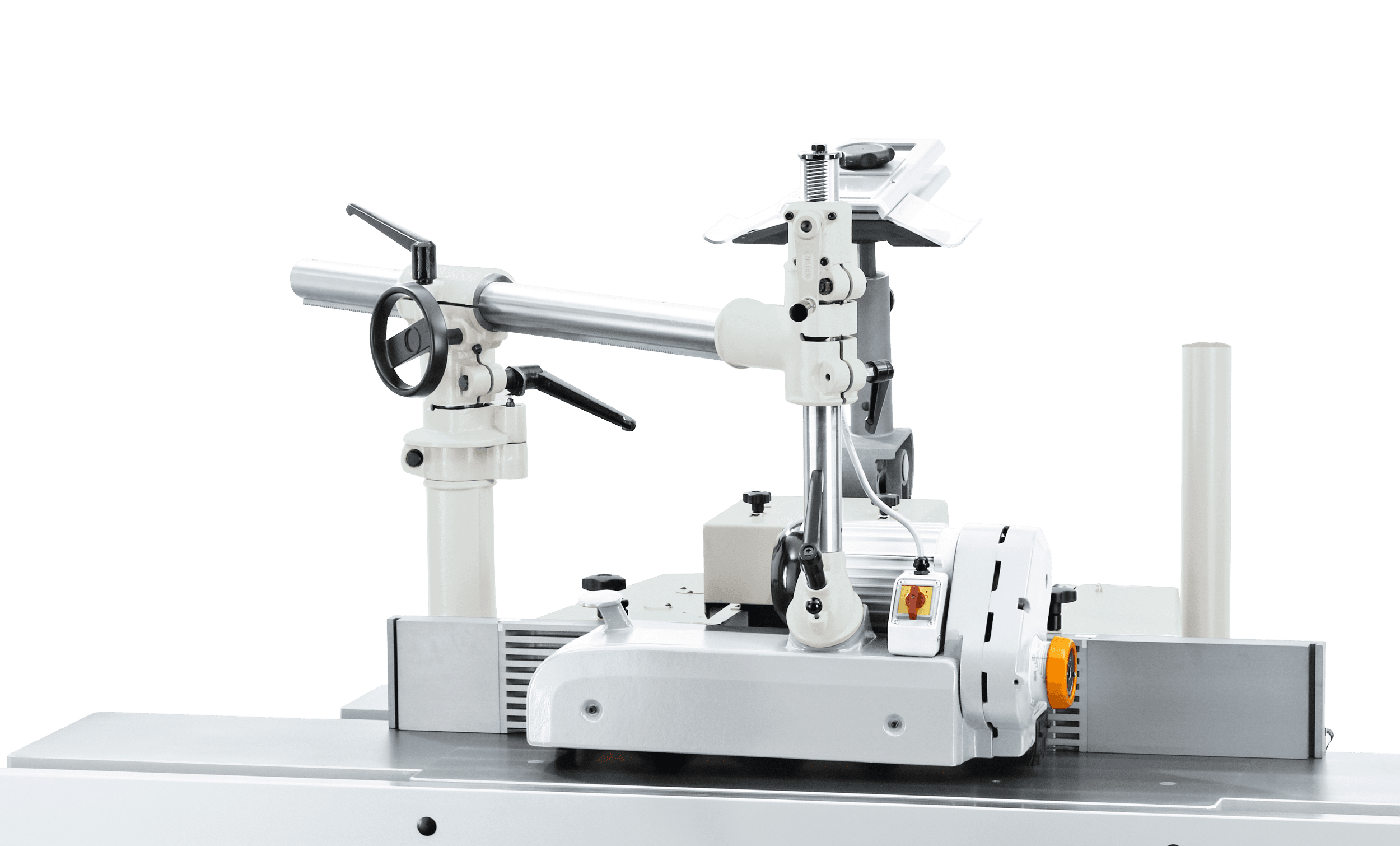

Variomatic 4N feed unit on comfort feed support

The winning feature of the comfort feed support is that it can be easily folded to the side and positioned with the MemoLock system. This means that, after folding it away, for example for a tool exchange, the feed latches back again exactly in the starting position. The height settings are very precise thanks to the digital height indicator, and height adjustment is quick and easy for the operator to carry out. Large locking levers ensure that the feed support can be clamped quickly and easily.

T14

T14

T14

T14

T14

Do not hesitate to contact us!

Suche