T27

Technology for today and tomorrow.

Setting up a spindle moulder is normally a big challenge. Not on the T27 FleX thanks to its modern touchscreen control: Through the integrated tool conversion you can also setup complex moulding patterns with tilted spindles in a instant. Only this enables the large tilting range of 2 x 46° to be used efficiently – and you can do it fully and completely to your inclinations. In addition the machine can be very precisely coordinated to your individual requirements in operation.

Since over 100 years

Made in Germany.

Cutter arbor clamping system HSK

Opt for the pneumatically operating HSK system. This system is ideal for any user who changes the complete tool/arbor units very often as it noticeably reduces set-up times. You can also use suitable CNC machining centre tools directly on the spindle moulder without any problem, thereby relieving this expensive machine from capacity-consuming traversing moulding tasks.

Small distances for great results.

On the T27, the electrically adjustable ring inserts, invented by MARTIN, are the perfect solution for closing the gap between the tool and the table in the best way possible. They are fully integrated into the control system and facilitate the set-up process enormously. By simply specifying a value or moving them manually, you can open or close the eccentric rings, and thus the gap, continuously. So at the start of the set-up process, you don’t need to know which fixed ring you need to insert into the table – you can simply adjust the gap quickly and easily at a later stage. It could hardly get any easier.

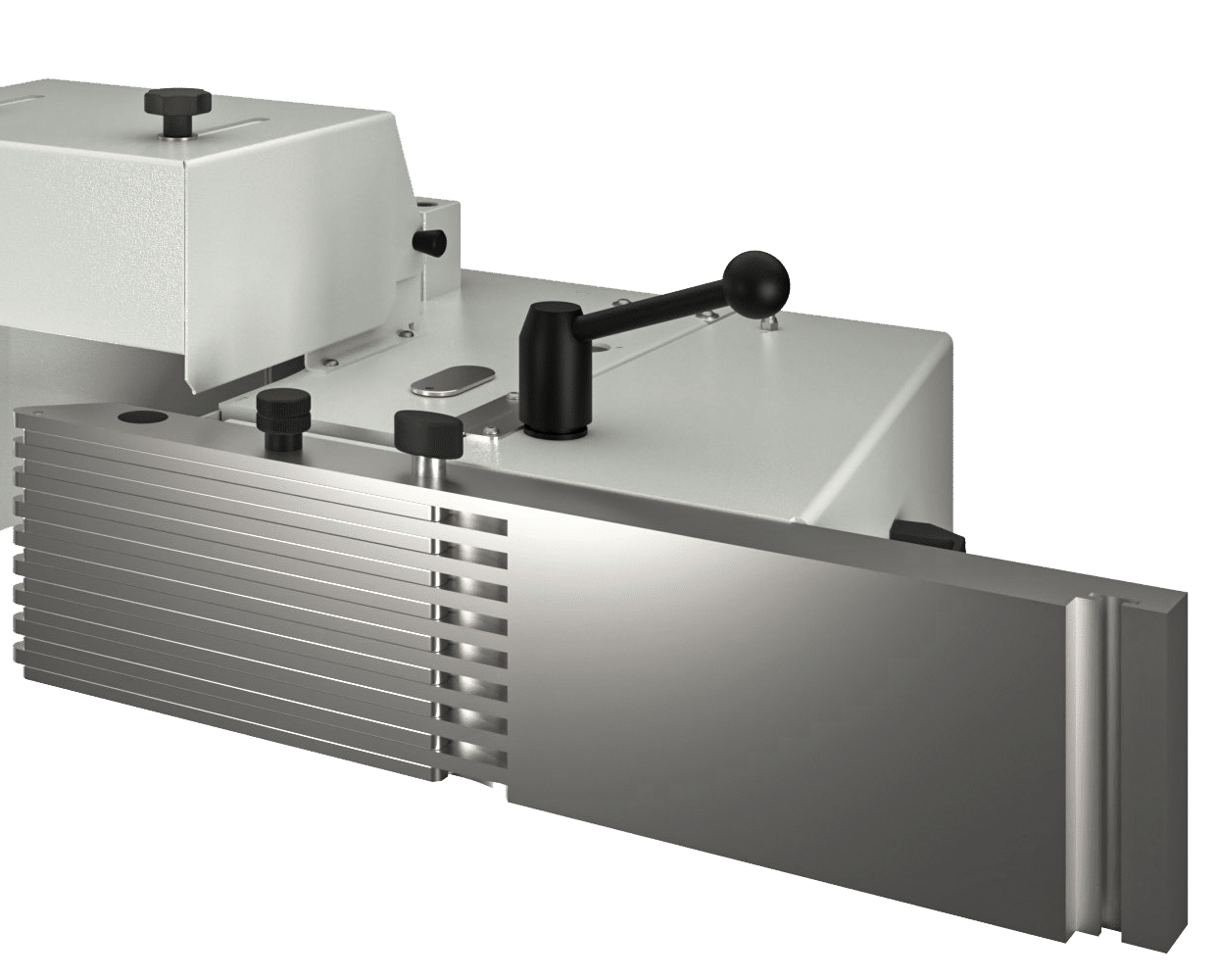

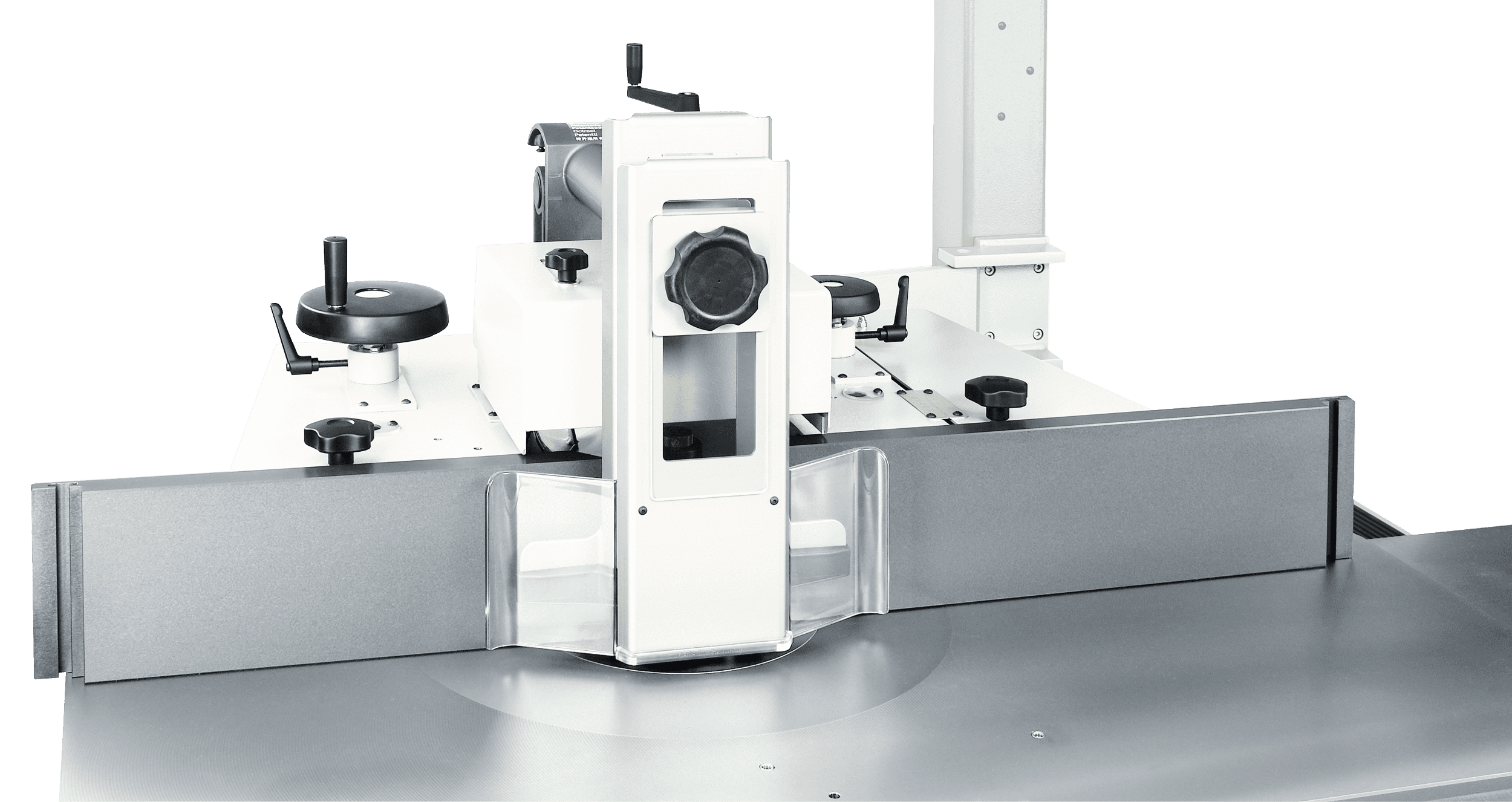

Fence jaws

The fence opening should always be closed in the firmly way so that the workpiece can be properly guided as it moves along the fence. This can be achieved with the tried and tested integral fence. The bars of the jaws, which are made of hard-coated aluminium, can be easily folded into position and released again, and the height position can also be varied.

The bar cassettes can be easily removed to allow working with a pre-set board.

Your material:

our strength.

What connects us with our customers: the passion for the precious material wood.

Anyone who works with wood must love it. The variety and the warmth it gives create enthusiasm for the most pristine of all materials. The wide range of possible applications offers room for creativity to unfold. Our machines are built for these passionate thinking and working people.

When plastic is your business!

The almost unlimited technical properties make plastics a fascinating material for a wide range of applications in trade and industry. MARTIN planers are the tools of choice when it comes to manufacturing these products. With our decades of experience in the machining of plastics, we always offer the perfect solution, even for very special machining operations.

Accurate results even with light metals.

Planing light metals and alloys with a weight content of less than 80 % magnesium is a demanding task for any sliding table saw. It is no coincidence that well-known aluminium processors rely on MARTIN. The robust construction, the powerful motors and the extensive accessories make the MARTIN planers the ideal tool for all those who value precise cutting.

More Highlights

More convenience with the feed support.

The electromotive positioning of the feed support with its ingenious latching mechanism provides genuine workload relief. The height adjustment of the feed unit can be easily specified and approached by the control system, and can also be integrated into the programs. The depth of the feed can be easily adjusted thanks to the ball-bearing guide.

And if the feed is not currently required, simply pivot it away to one side without losing any of the settings you made previously.

Fence jaw clamping system AutoLock

Fence jaws need to be moved on a regular basis in order to optimise the fence opening to suit the tool.

But all too often, clamping is forgotten about afterwards and the jaws are damaged. The optional AutoLock fence jaw clamping system ensures secure clamping of standard and integral fence jaws in a simple and safe manner. The jaws are always clamped securely by spring force and the clamping is only released for setting with the easily accessible levers. Completely without any electrics or pneumatics.

A patented solution: Collision detection and collision avoidance

If, during the set-up process, a tool is accidentally moved onto a collision course, the machine, which is equipped with continuous rotational speed control, detects this and warns the operator. This ensures the highest degree of safety,even for inexperienced operators. The machine software prevents collisions between the machine components (not tools) in the border areas of the travel paths of the table rings and the spindle sleeves. This significantly helps the machine to retain its value.

Fence plates

The moulding guard is a very important safety guard for moulding with hand feed. Compared to the CPS guard, the CENTREX

guard offers a significant advantage in terms of convenience. It boasts perfect functionality, an attractive design and optimal

placement on the fence housing. All the functions can be set quickly and easily in just a few steps and without tools. The special

shape of the pressure shoes guarantees precise workpiece guidance with high visibility of the work step. Pressure can also

be applied to the workpiece for insert cutting.

Arbor quick-change systems

The DornFix standard quick-change system is the perfect solution for everyone wishing to adjust the arbor diameter time and again. On the other hand, the HSK quick-change system is the number one choice for power users who often change the arbor of the complete arbor/tool units.

The system works fully tool-free and is compatible with the CNC processing centres of leading manufacturers. So you can use suitable CNC machining centre tools directly on the spindle moulder without any problem, thereby relieving this expensive machine from capacity-consuming traversing moulding tasks.

T27

T27

T27

Do not hesitate to contact us!