T45

Quickly and quietly delivers precise planing results.

The T45 planer offers the ideal conditions for modern production: it supplies cleanly planed surfaces, is quick and easy to operate and also works extremely quietly. Thanks to a memory space for 99 planing dimensions, the standard electronic control system makes adjusting the planing height so easy that even the very first workpiece fits perfectly. Of course, the thicknessing table can also be moved or raised upwards in steps of 0.1 mm simply by pressing a button. The feed control elements are also within easy access.

With its high-quality cutter block, the sturdy, vibration-damping composite frame is a guarantee for excellent surfaces. Thanks to the sound-absorbing design, you can work quietly even with the standard version. If you opt for the Xplane spiral cutter block, you will hardly be able to hear the machine at all.

Since over 100 years

Made in Germany.

TERSA cutter block

Through the use of different cutter blocks, the T45 can be perfectly adapted to the tasks required of it. Thanks to the standard TERSA solid steel cutter block with its form-locked knife holders, all surfaces can be planed perfectly. It just takes a few seconds to change the blades. TERSA reversible blades are available in different qualities and with different geometries, so the right blade is available for every task. In addition, by using two dummy blades, the standard Z4 cutter block can also be operated as a Z2 cutter block.

Thin board planed – down to a residual thickness of

MARTIN is probably the only manufacturer in the world to offer the possibility of planing wood and also plastics down to a residual thickness of 1.5 mm. In particular, the impact resistance at the inlet and outlet is extremely impressive. These options were developed to meet the requirements of plastics processing, however they are appreciated by those working on the finest wood surfaces too. That not only includes specialists, such as instrument or model makers, but also carpenters with particularly high demands.

Contour

T45 Contour

Staying flexible.

In general, a thickness planer can do one thing above all else – it can plane workpieces to thickness. With the T45 Contour, MARTIN is offering a machine which, in addition to thickness planing, can also profile entire surfaces. This means that with this machine, profiled seat surfaces, grooved terrace decks, round bars and so much more can be produced quickly and easily. Make the most of these possibilities!

The perfect basis for perfect work.

The T45’s machine frame is a stable, thick-walled composite structure of a type and perfection that is unique to MARTIN. This design was invented by Otto Martin and granted a utility model way back in the 1920s.

Following 100 years of continuous improvements, MARTIN still uses this very simple yet ingenious principle of frame construction today. The intelligent combination of the two materials, steel and concrete, creates a high-quality frame that is unparalleled in terms of stability, damping capacity and torsional rigidity. The vibrations that occur on every thickness planer are absorbed far more effectively than with welded constructions.

Your material:

our strength.

What connects us with our customers: the passion for the precious material wood.

Anyone who works with wood must love it. The variety and the warmth it gives create enthusiasm for the most pristine of all materials. The wide range of possible applications offers room for creativity to unfold. Our machines are built for these passionate thinking and working people.

When plastic is your business!

The almost unlimited technical properties make plastics a fascinating material for a wide range of applications in trade and industry. MARTIN planers are the tools of choice when it comes to manufacturing these products. With our decades of experience in the machining of plastics, we always offer the perfect solution, even for very special machining operations.

More Highlights

Switching and controlling for professionals.

All of the T45 control elements are centrally arranged in a clearly laid out manner. When the start button is pressed, the machine starts up smoothly. One press on the stop button is sufficient to electrically brake the cutter block without causing wear or tear. The switching elements for the feed are also within easy access. Either as standard with speeds of 6 and 12 m/min or continuously adjustable, as an option.

Thanks to a memory capacity for 99 planing dimensions, the electronic controls make adjusting the planing height so easy that even the very first workpiece fits perfectly. Of course, the thicknessing table can also be moved or raised upwards in steps of 0.1 mm simply by pressing a button.

That’s how easy profiling is – with the T45 Contour.

Profiling with a planer – it’s as easy as it looks. Profile blades, which you can have made at any tool grinding shop, are inserted radially into the cutter block, aligned with the setting gauge, which is supplied as standard, and tightened. Now you just need to specify how the workpiece should be guided on the machine table. Thanks to the corresponding dimensional scales on the table and setting gauge, this step takes no time at all.

That’s how easy it is to achieve a previously unimaginable variety of new products and possibilities with the T45 Contour. Wherever wide profiles have to be produced in one pass, the T45 Contour is your number one choice.

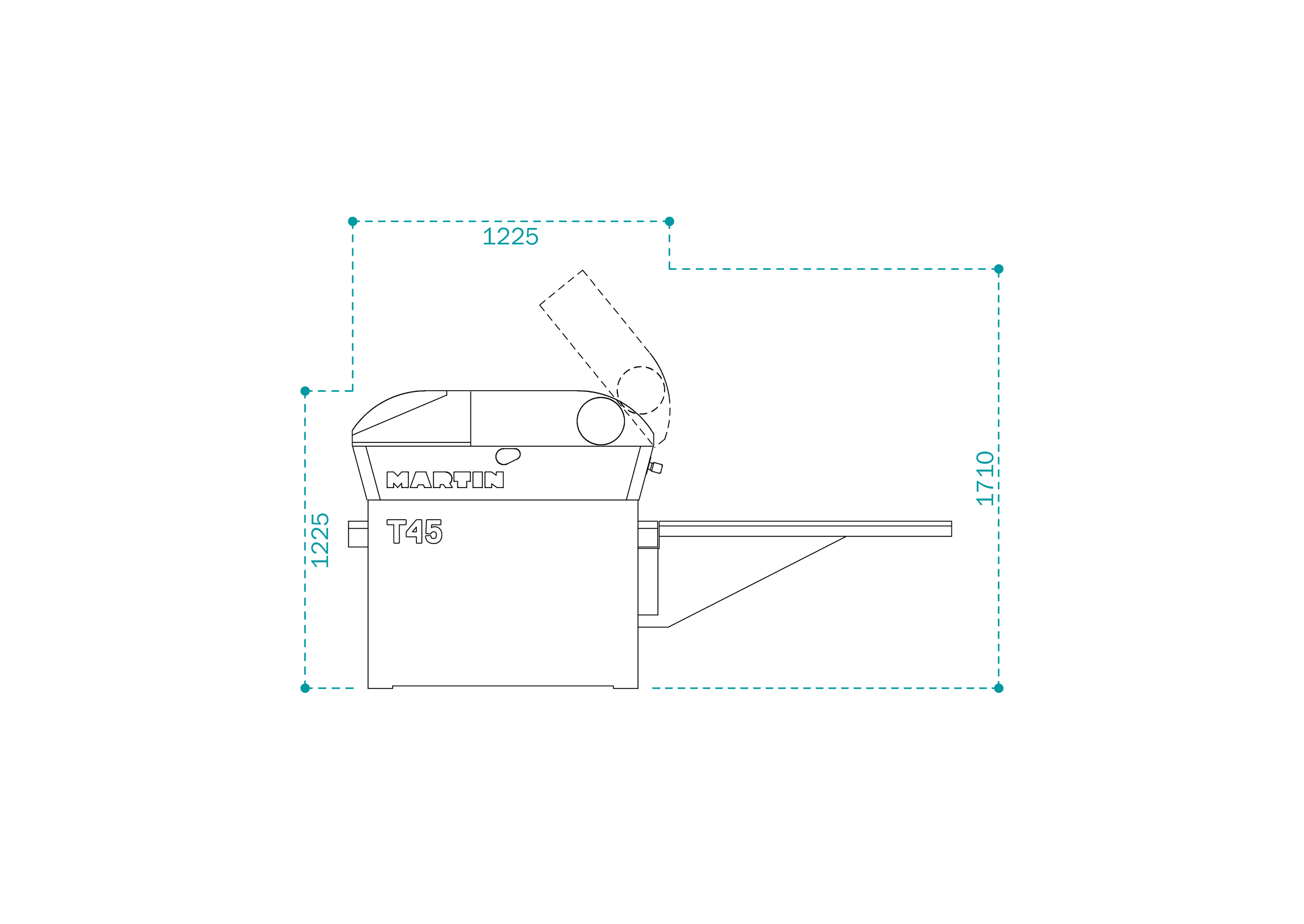

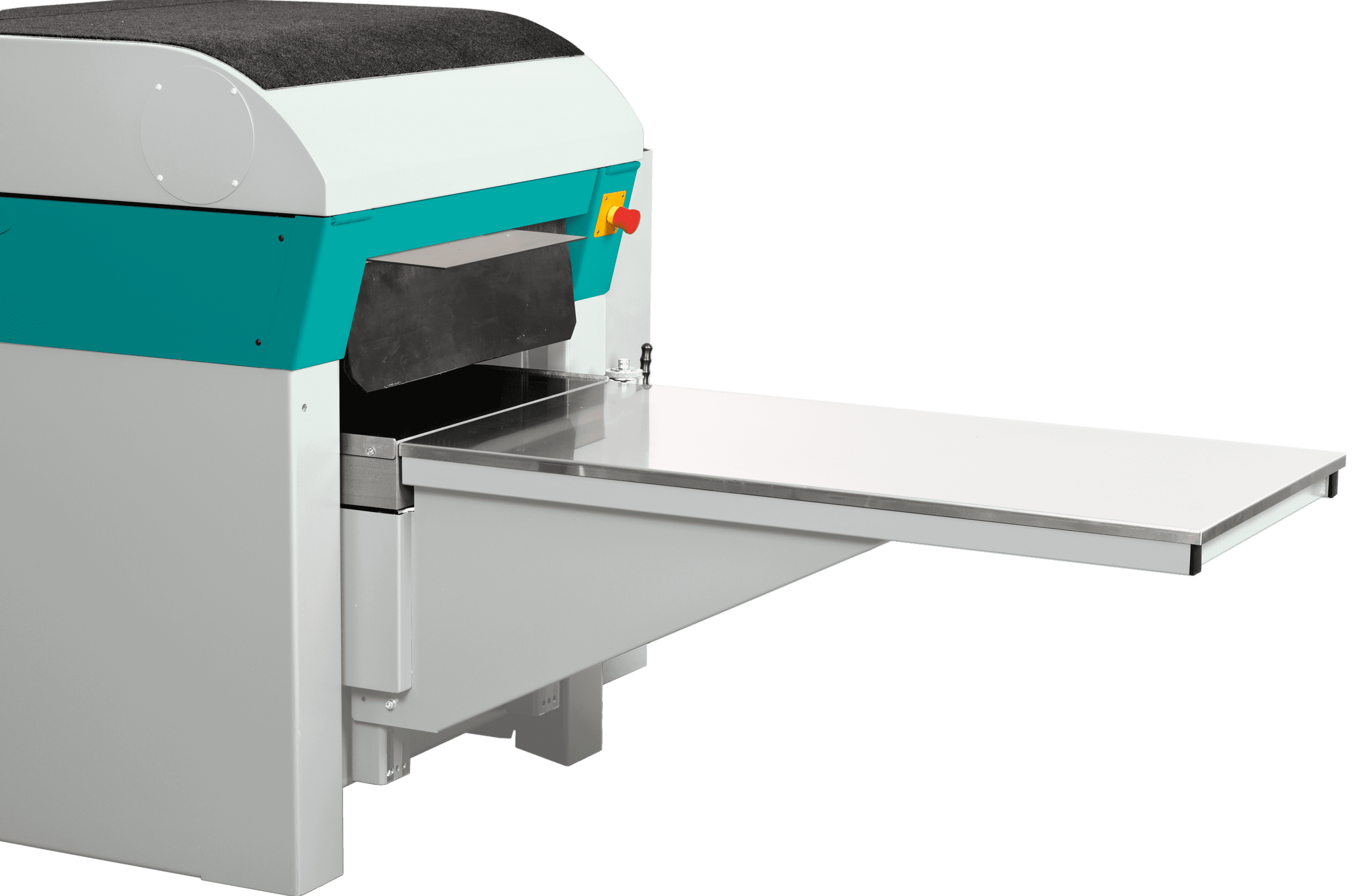

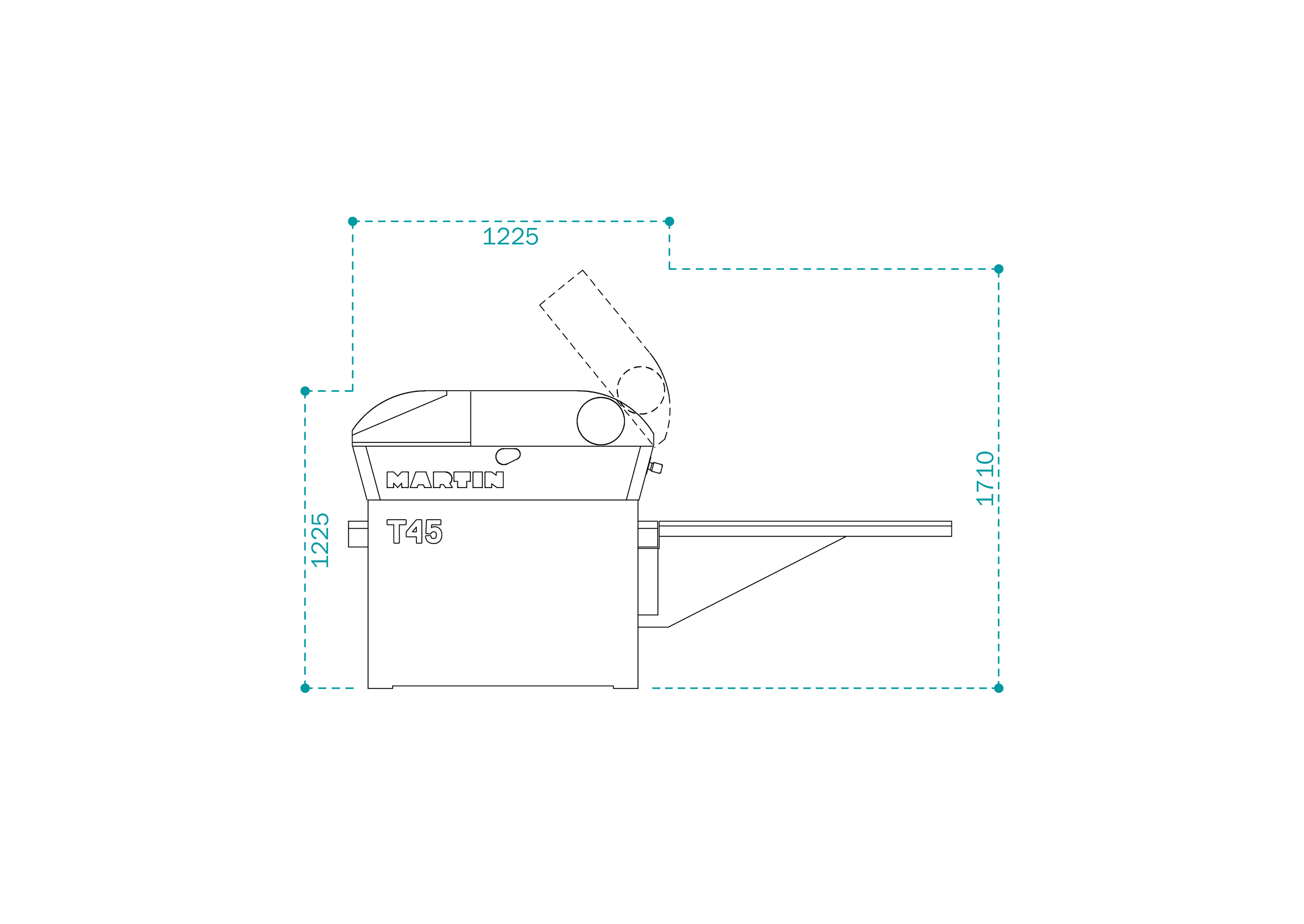

Machine table and extensions

The T45’s machine table is finely planed, which offers unbeatable advantages when working with wet woods. For processing larger cross-sections, for example in carpenter’s shops, the thicknessing table can be equipped with adjustable table rollers.

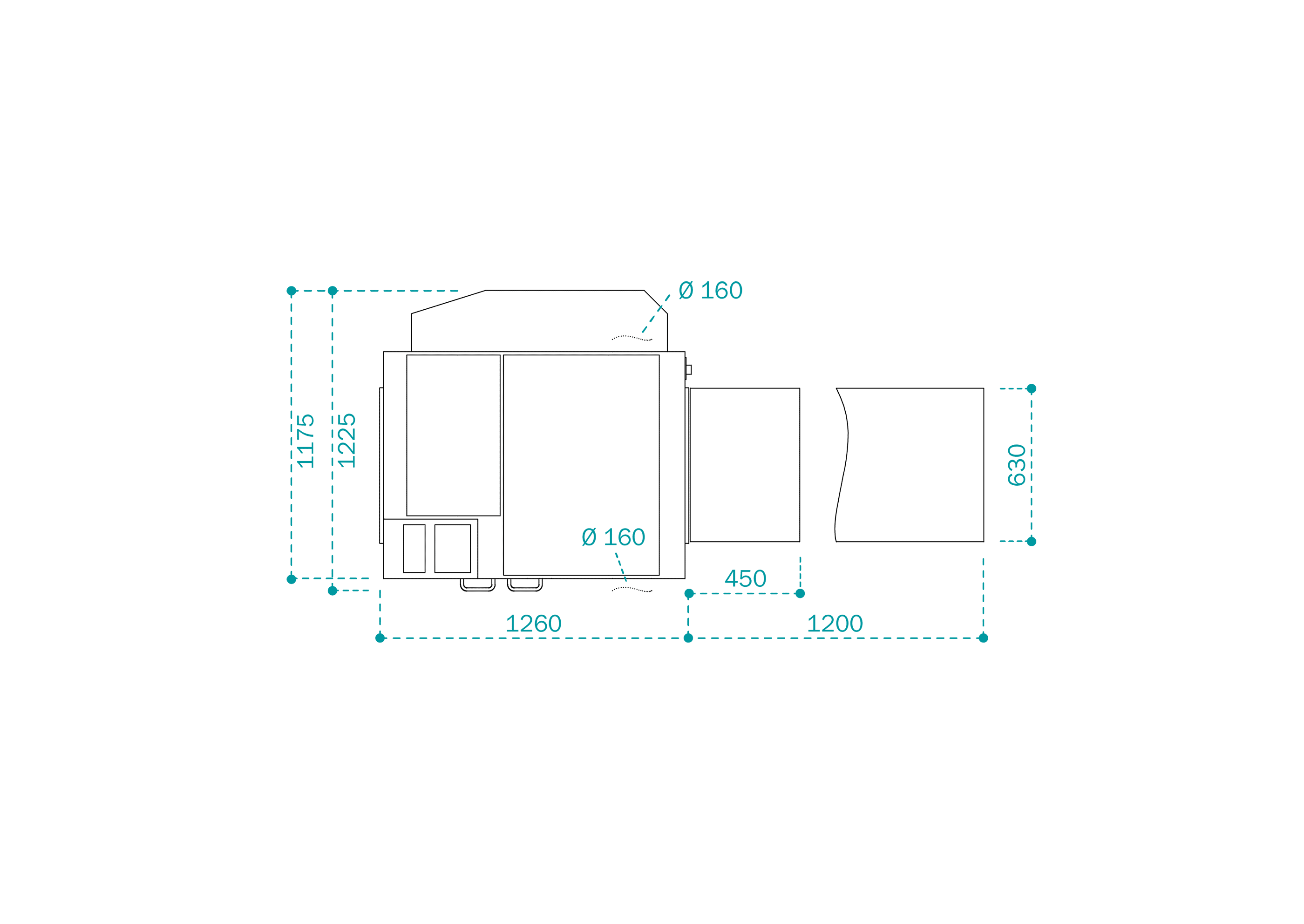

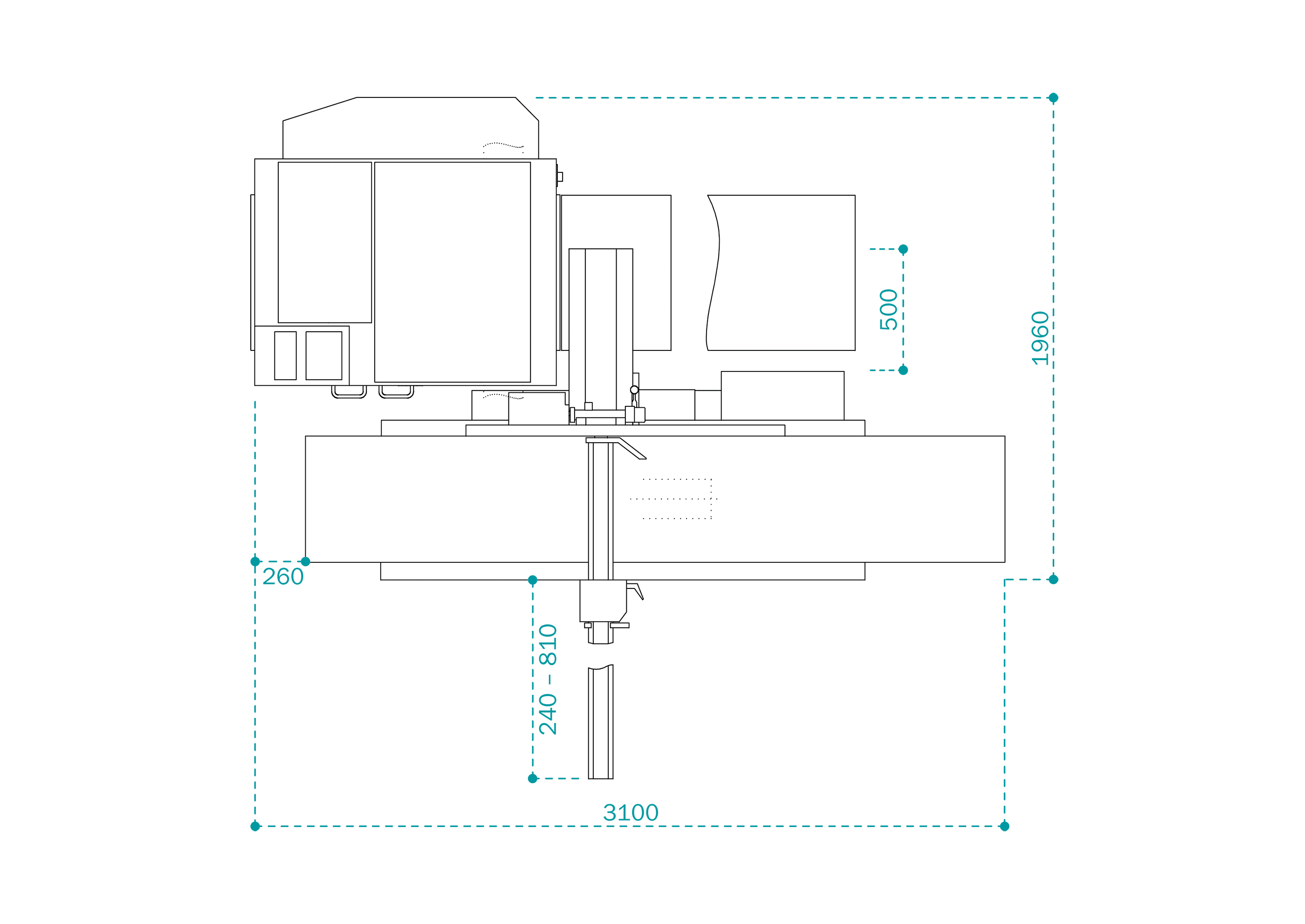

The automatic lubrication located on the front of the table lubricates the underside of the incoming material. This option can be easily and quickly switched on or off. In order to support outgoing and incoming workpieces, the machines can be equipped with table extensions of 450 and 1,200 mm length. The short variant can be mounted on the incoming or outgoing side. This variant can also be folded up to save space. And yet, at the same time, you can still make full use of the planing height. If you process very delicate workpieces, you can also opt for a table with a ground surface. This variant offers particular advantages, especially for plastics processing.

Blade changes – in seconds, with TERSA.

Thanks to the TERSA cutter block with its form-locked knife holders, all surfaces can be perfectly planed. It takes less than a few seconds to change blades. Available in various qualities, TERSA reversible blades offer the perfect blade for every task. In addition, by using two dummy blades, the standard Z4 cutter block can also be operated as a Z2 cutter block.

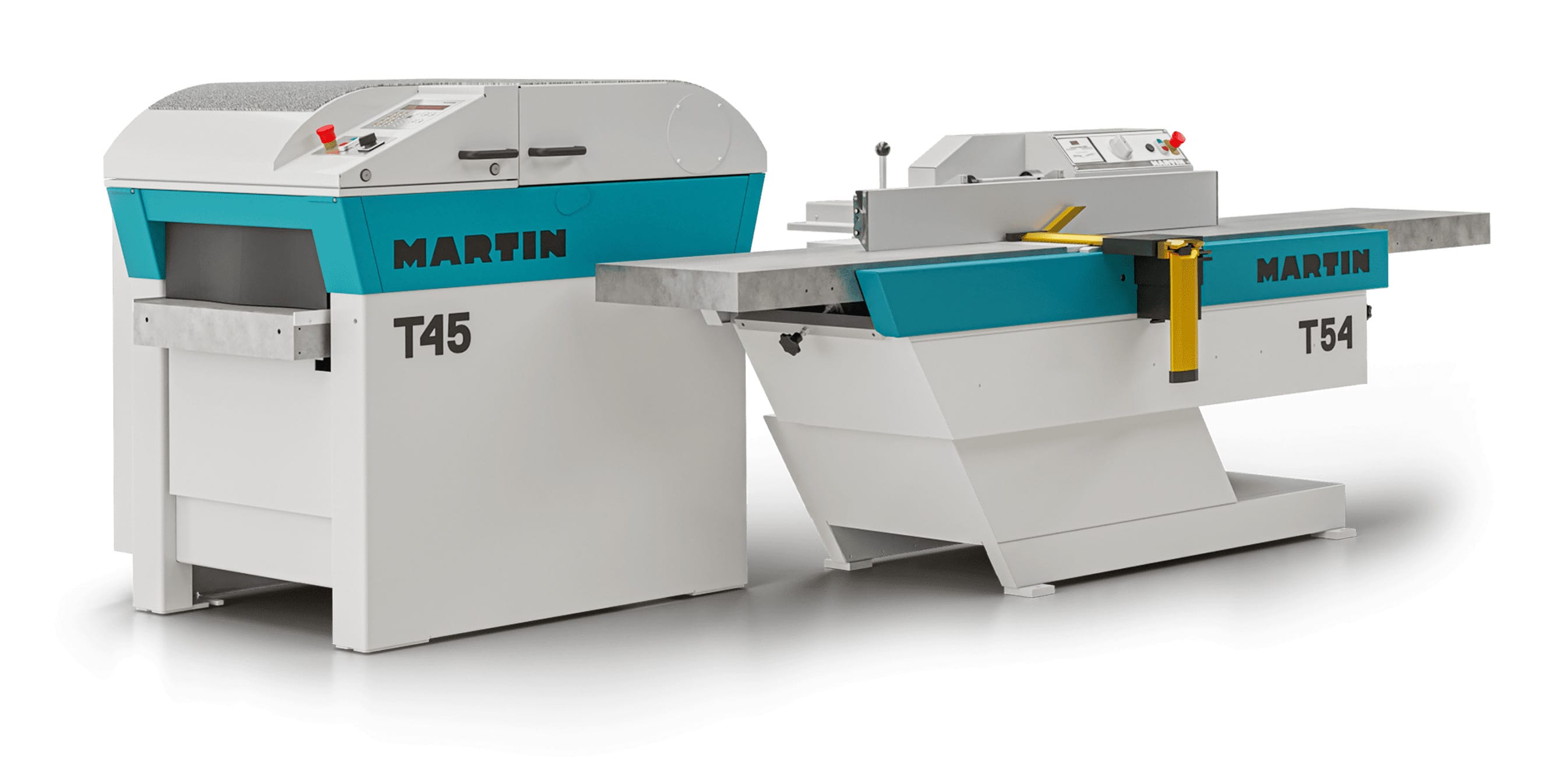

T45 and T54: two singles – making up a perfect couple.

With the T54 surface planer and the T45 planer, you get two specialists which complement each other to perfection. Unlike with a combined planer, each of the machines is designed for its respective task without any compromises. The machine that you currently require is available immediately without requiring conversion. Thanks to the space-saving installation, the planer and the surface planer together take up hardly any more space than a combined machine. And what’s more, the individual machines can be operated in parallel without any restrictions. This has particular advantages especially when working on time-critical orders. An important advantage when working on time-critical orders is that the two individual machines can be used separately.

View T54

T45

T45

T45 & T54

Do not hesitate to contact us!

Suche