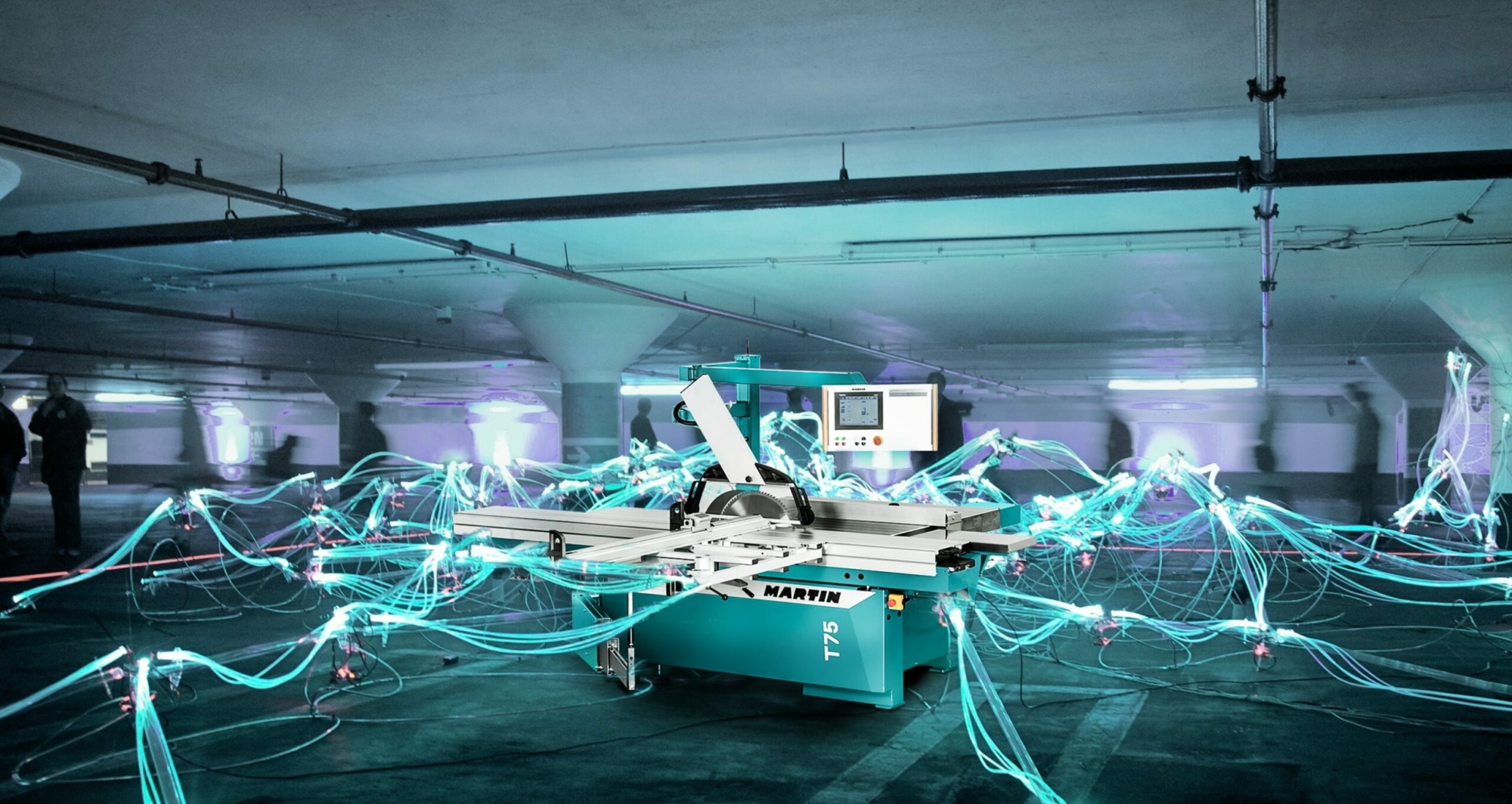

Precision and robustness

Monument conservation at the highest level

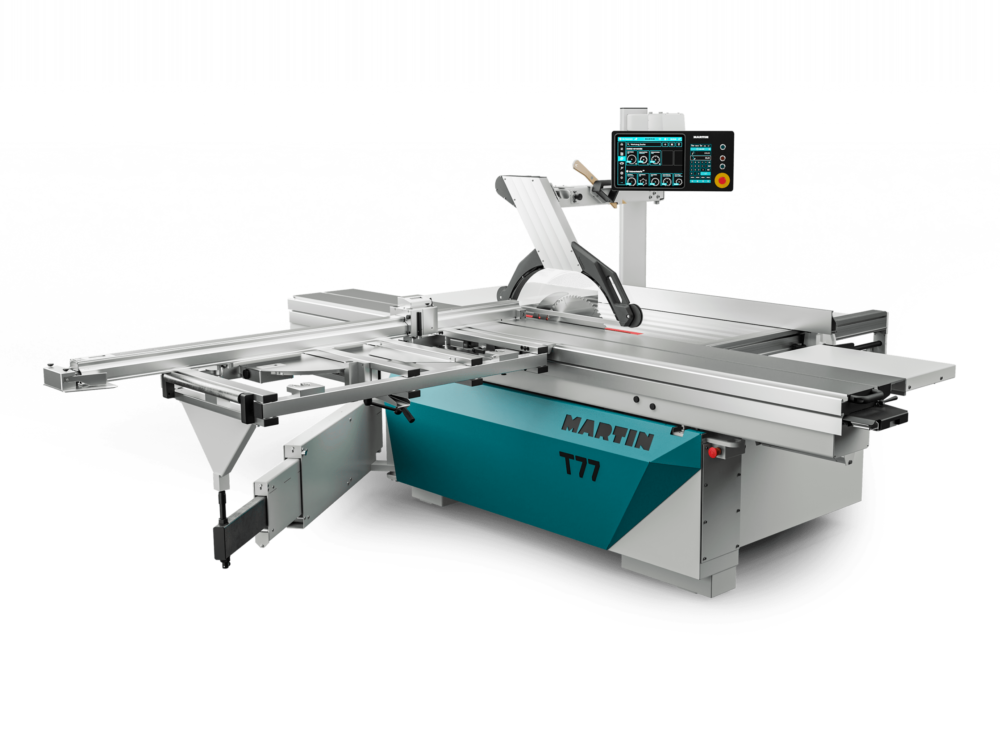

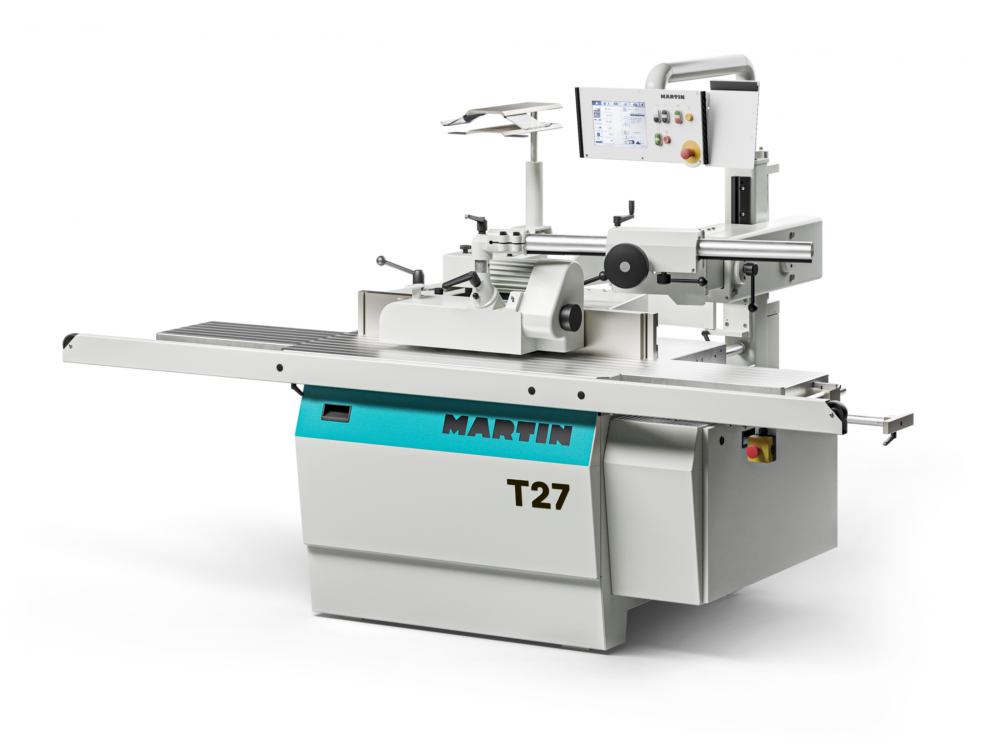

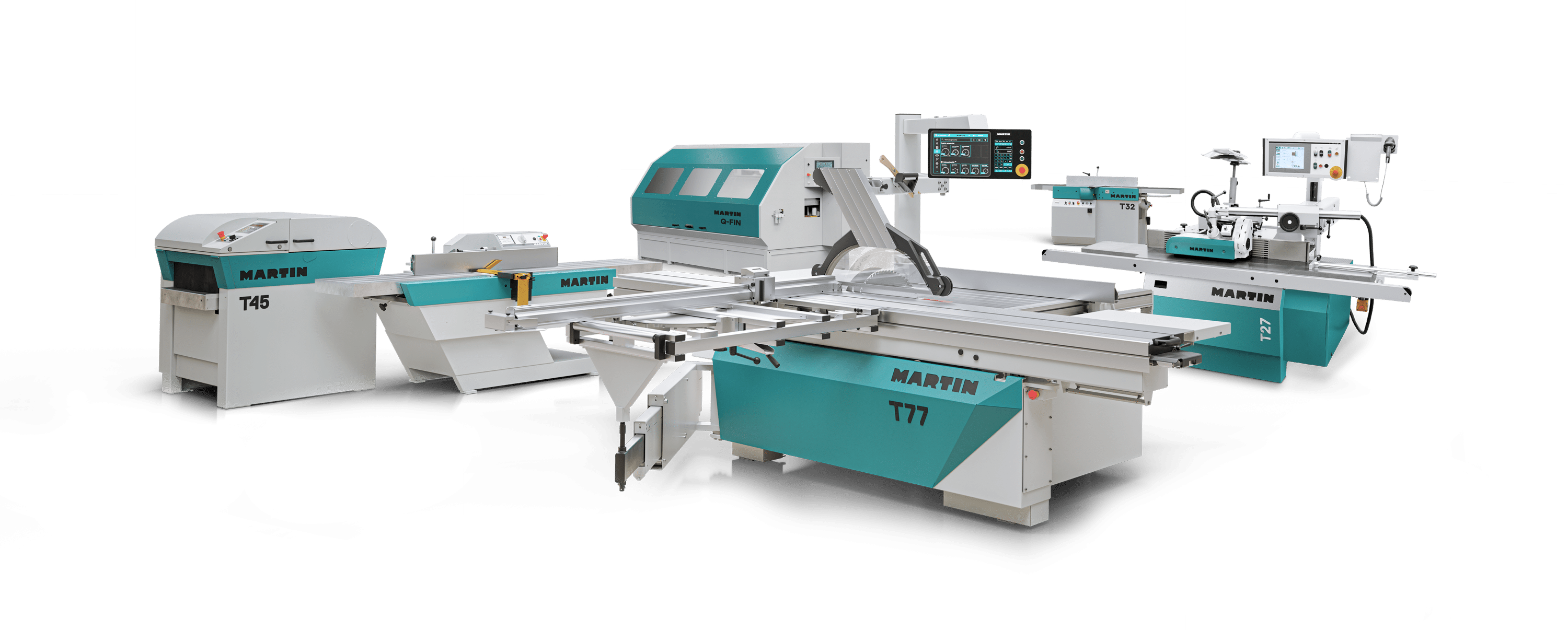

Since the political change in 1989, we have been working with MARTIN machines. We appreciate the precision and at the same time the robustness of the machines as well as the good usability. They are not only well thought out, but also well manufactured. The reliability of the machines, as well as the service, makes working with MARTIN uncomplicated and pleasant. Many thanks to all employees!

Jörg Spatzier M.A.

Joinery Spatzier GmbH